Located in the heart of Louisiana’s Cajun country, Machine Specialty & Manufacturing Inc. strives to achieve the highest level of quality and reliability in meeting our customer’s needs.

MSM was founded in 1982 by its president, Andy Vigé. He grew the company by providing quality work and unmatched customer service.

Our Youngsville facility features over 75 CNC machining centers, in-house NDT, stress relieving furnaces, welding, repair and assembly facility, and hydrostatic testing.

At Machine Specialty, we take the safety of our employees very seriously. Under the guidance of our Safety Director, mandatory programs have been implemented which greatly reduces the risk of workplace injuries and illnesses. Monthly meetings stress the importance of job specific hazards and allow our employees to express their concerns about their working environment.

Machine Specialty & Manufacturing, Inc. is an independently run and privately owned company which prides ourselves in providing quality compliant products, on time delivery, and our ability to be a nimble and responsive partner to each and every company’s needs.

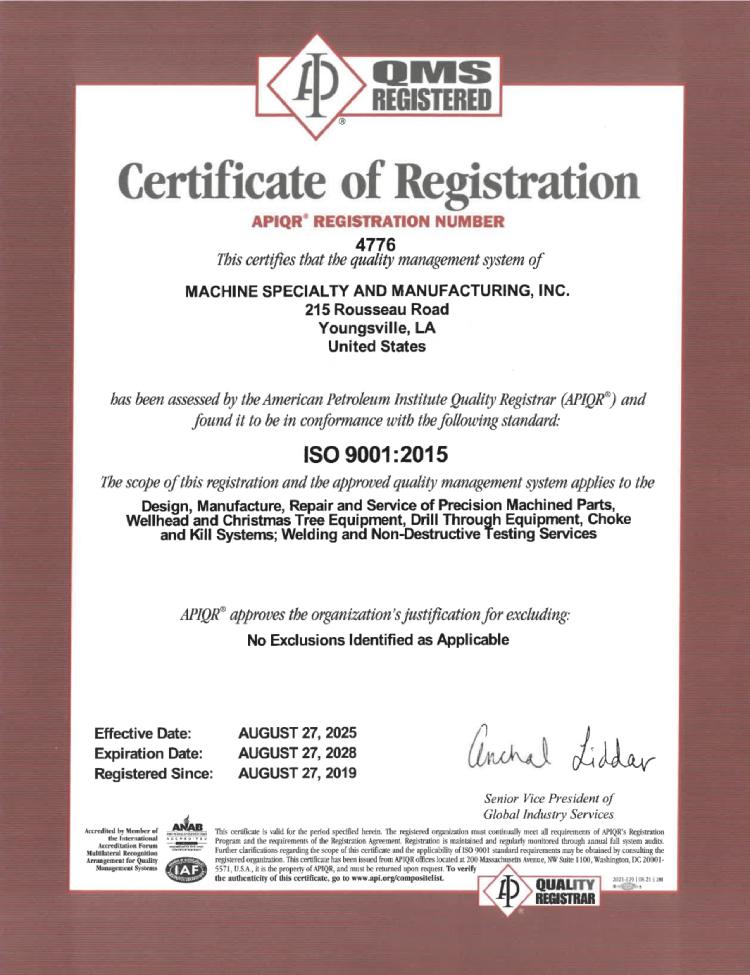

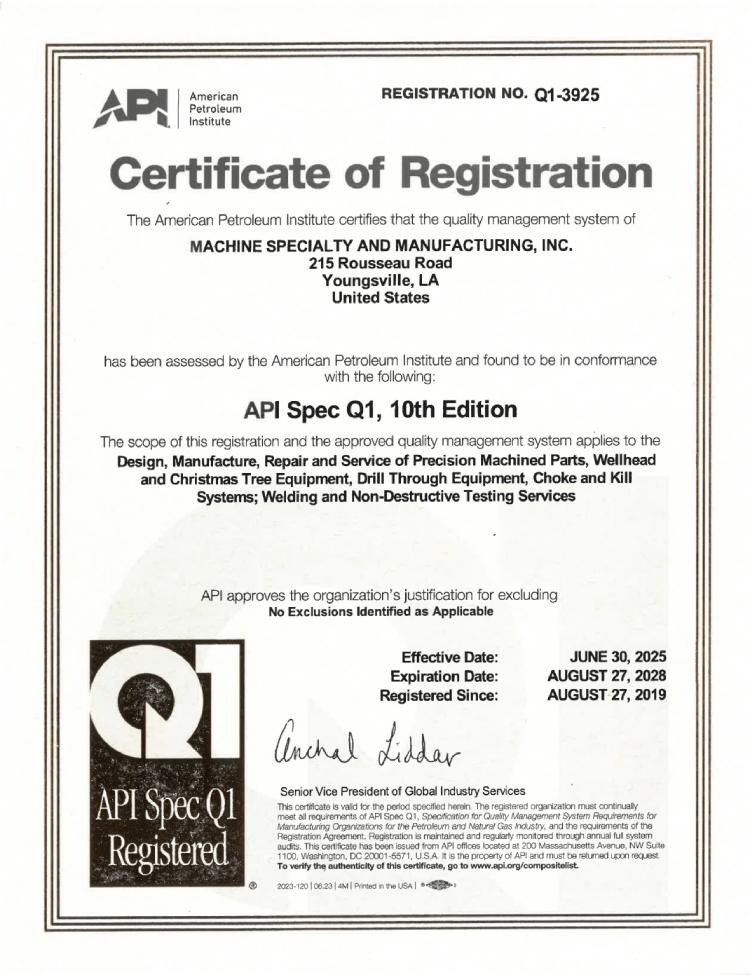

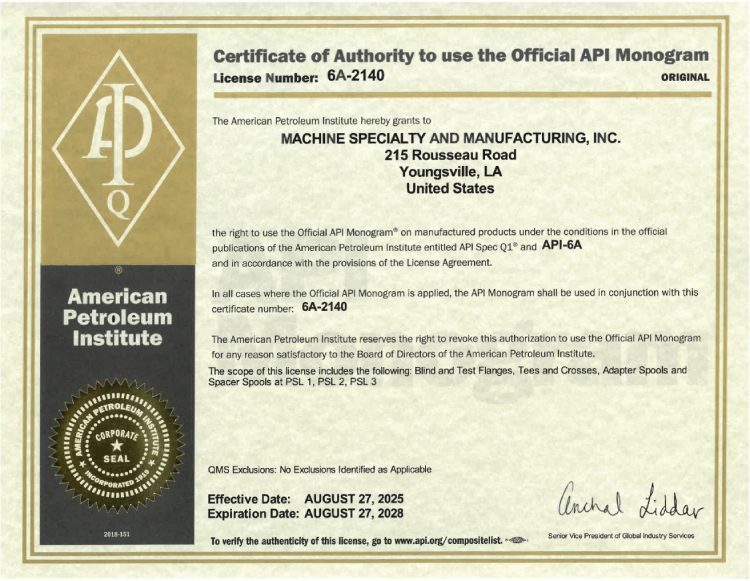

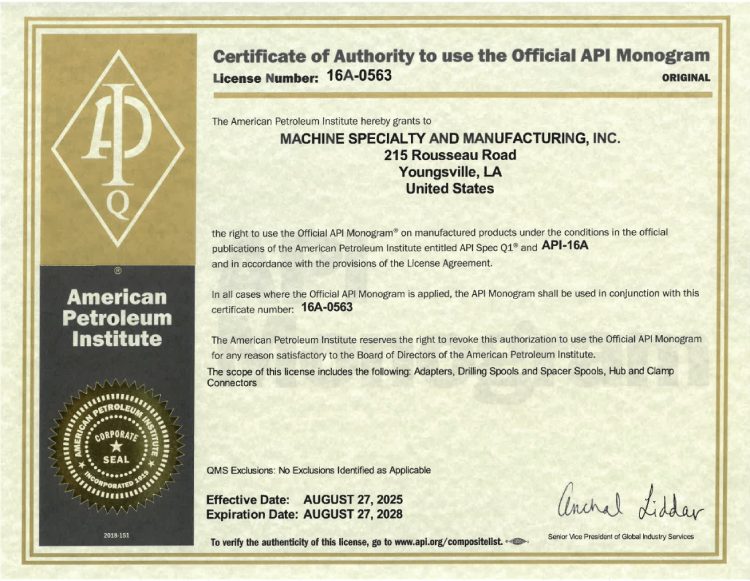

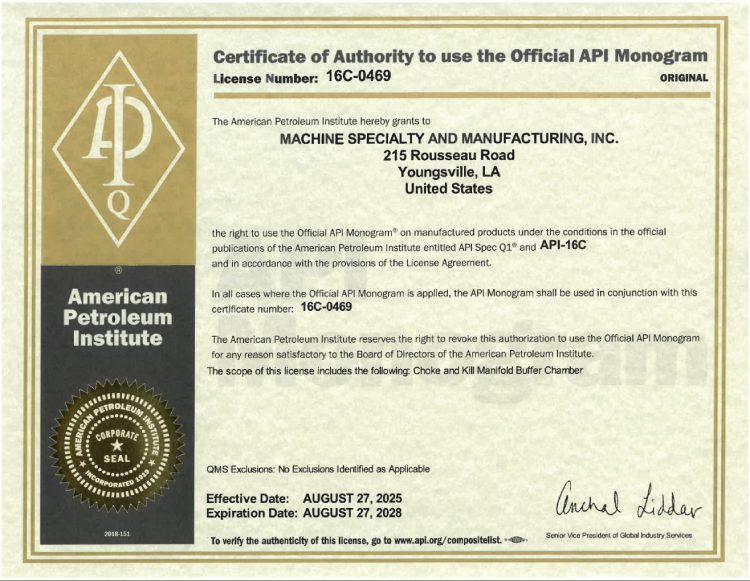

Machine Specialty & Manufacturing’s API and QSM registrations offer significant benefits to customers in need of API flanges, fittings and weldments. These registrations ensure that products meet the stringent standards set by the American Petroleum Institute (API) and Quality System Manual (QSM), guaranteeing their quality, reliability, and safety. This translates to peace of mind for our customers, knowing they are getting API-approved products that can withstand the demanding conditions of the oil and gas industry.

Additionally, API and QSM registration streamline the procurement process, as customers can be confident that MSM’s products comply with industry regulations, eliminating the need for additional inspections or certifications. Ultimately, these registrations demonstrate our commitment to providing superior quality products that meet the specific needs of the oil and gas sector.

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.