API Flanges for Your Most Demanding Operations

When Failure Is Not an Option

In the high-stakes world of oil and gas operations, the integrity of your pressure containment systems can mean the difference between smooth operations and catastrophic failure. Every connection point in your wellhead, Christmas tree, or BOP stack represents both a critical necessity and a potential vulnerability.

API flanges are the unsung heroes of your operation—the components that must withstand extreme pressures up to 20,000 psi, corrosive environments, and temperature fluctuations without compromise. When these connections fail, the consequences extend far beyond simple equipment damage:

In an industry where downtime costs can run into hundreds of thousands of dollars per day, equipment failure isn’t just an inconvenience—it’s a financial emergency. More importantly, pressure containment failures pose serious safety risks to your personnel and potentially devastating environmental consequences.

Meeting rigorous API specifications isn’t optional—it’s essential for operational compliance and your company’s reputation for safety and reliability.

Your Trusted Partner For API Flange Manufacturing

At Machine Specialty & Manufacturing (MSM), we’ve dedicated ourselves to mastering the precise art and science of API flange manufacturing. We understand that your reputation rests on the quality of every component in your pressure system.

Having served the oil and gas industry for years, we’ve witnessed firsthand the challenges you face—increasingly demanding operating conditions, stricter regulatory requirements, and the constant pressure to minimize downtime while maximizing safety and efficiency.

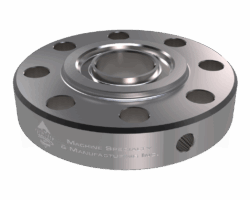

Our facility is equipped with state-of-the-art forging and machining capabilities, enabling us to deliver API flanges that meet or exceed the most stringent requirements. As an API Monogram licensed manufacturer, every flange we produce undergoes rigorous quality control processes and comprehensive testing to ensure absolute reliability when it matters most.

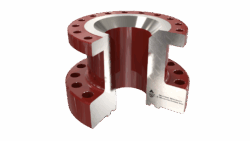

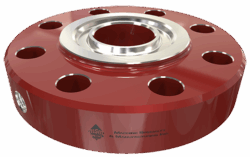

Comprehensive Solutions for Any Pressure Challenge

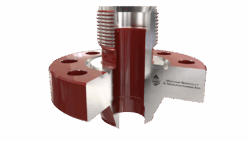

Whatever your specific pressure containment needs, MSM delivers API Flange solutions engineered for absolute reliability:

|

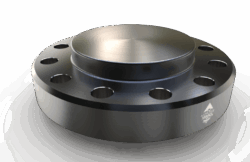

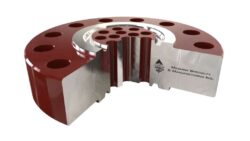

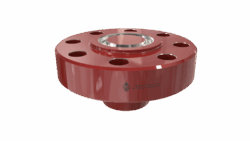

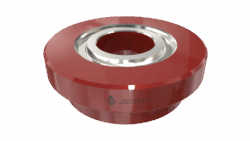

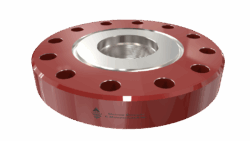

Type 6B Flanges (2,000-5,000 psi) |

|

|

|

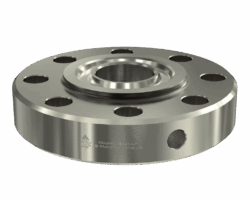

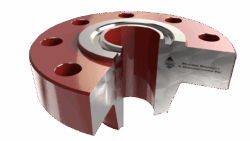

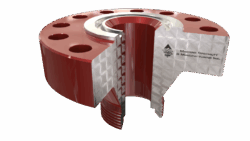

Type 6BX Flanges (2,000-20,000 psi) |

|

|

|

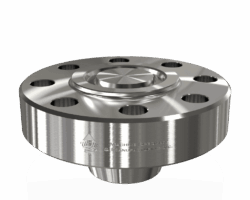

Specialty Configurations |

|

|

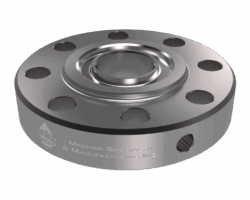

Our manufacturing process incorporates comprehensive quality assurance at every stage of API flange manufacturing —from material selection through forging, heat treatment, precision machining, and final testing. We offer a wide range of material options suitable for general service, sour service (compliant with NACE MR0175/ISO 15156), and severe subsea environments requiring corrosion-resistant alloys.

API Flange Product Categories

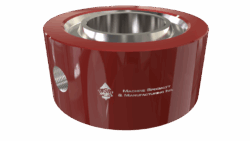

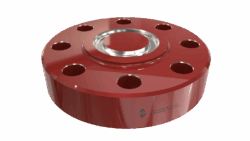

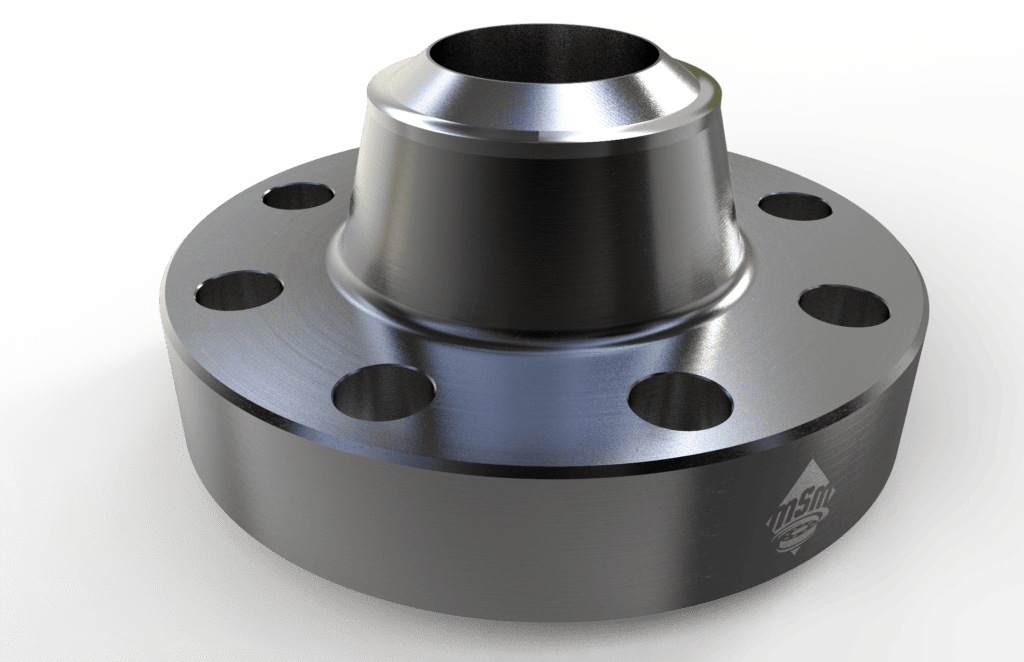

API Flange Gallery

Experience the MSM Difference

When you choose MSM for your API flange needs, you’re not just purchasing pressure-containing components—you’re investing in operational confidence.

Our customers consistently report exceptional field performance under the most demanding conditions. MSM flanges maintain reliable containment integrity in extreme environments—from deepwater subsea applications to high-pressure, high-temperature wellhead operations, and sour service conditions where failure is not an option.

By partnering with MSM, you ensure full compliance with all relevant API standards, including API 6A, API 17D, and related specifications. Our meticulous attention to dimensional accuracy, material quality, and manufacturing precision translates directly into reduced maintenance issues and fewer operational disruptions.

We understand that timing is critical in your industry. That’s why we’ve optimized our manufacturing and quality processes to deliver consistently on schedule, helping you avoid costly project delays while never compromising on quality.

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.