The Confidence You Need: How Our NDT Services Protect Your Assets

Here at MSM, we know you can’t afford to take any chances with your critical components. Your team’s safety, your operations’ reliability, and your reputation for quality all depend on one thing: uncompromising integrity. That’s why we take our in-house Nondestructive Testing (NDT) services so seriously. We don’t just run tests; we give you peace of mind and deliver the engineered confidence you need to succeed.

Our full-time team includes two certified ASNT Level II technicians. This certification means they’ve completed rigorous training and passed tough exams. Our experts bring a high level of skill and professionalism to every project. They work diligently to ensure every test is done with pinpoint accuracy. Think of them as your personal quality assurance squad. We’ve built our services to seamlessly integrate into our manufacturing and repair processes. This gives you top-notch quality without unnecessary delays.

Your Takeaway: Bring our team in at the start of your project. We can help you identify potential quality risks early and develop a robust inspection plan that gives you complete confidence in the final product.

A Look Inside Our Testing Methods

We offer a complete suite of NDT services, and each one helps us find specific flaws without ever having to damage your parts. MSM has two full time ANST Level II technicians on staff to perform the tests/inspections. It’s like having a team of specialized detectives for your materials.

Ultrasonic Testing (UT)

We use high-frequency sound waves to look inside your components. By sending these sound waves in and listening to the echoes, our technicians can find hidden flaws like cracks, voids, or other internal defects. Ultrasonic Testing is an absolute must for checking the integrity of welds and castings, especially for parts that must handle a lot of pressure.

Magnetic Particle Inspection (MPI)

When we need to find tiny cracks or flaws on the surface, we turn to Magnetic Particle Inspection. We apply a magnetic field to the part and sprinkle a fine iron powder over the surface. Any imperfections disrupt the magnetic field, and the powder gathers there, showing us exactly where the problem is. This gives us a fast and reliable way to check for surface flaws on any magnetic metal.

Liquid Penetrant Testing (LPT)

For non-magnetic parts, Liquid Penetrant Testing is the perfect solution. We apply a colored or fluorescent liquid to the surface. It soaks into any tiny cracks. After we clean off the excess, we apply a developer that pulls the liquid back out of the cracks. This makes the flaws stand out clear as day. LPT is a go-to method for everything from welds to forgings.

Radiographic Testing (RT)

Radiographic Testing is an X-ray for your parts. We use X-rays or gamma rays to create an image of the internal structure of a component. This lets us see volumetric defects like porosity, inclusions, or incomplete fusion in welds. RT is a primary method for ensuring welds are perfectly formed and meet every code and specification.

Your Takeaway: Your project might require a specific test or a combination of several. We recommend you discuss your application’s unique demands with us. We will help you select the exact testing methods you need to guarantee the integrity of your components.

The Details That Make a Difference

Beyond our core inspections, we offer specialized tests that give you a complete picture of your component’s condition and properties.

Positive Material Identification (PMI)

Mistakes happen, but not when it comes to your materials. With Positive Material Identification, we can quickly verify the exact chemical makeup of your component. This is a huge deal for critical applications, as it ensures you’re using the right alloy for the job and eliminates any risk of material mix-ups. You know the metal is exactly what it’s supposed to be.

Visual Inspection (VT)

You can’t skip the basics! Visual Inspection is always the first, and most important, step. Our certified technicians meticulously check components by eye, looking for any visible issues like cracks, corrosion, or dimensional problems. This essential step ensures everything looks right and is built with the kind of care and quality you expect.

Hardness Testing

How tough is your material? Hardness Testing gives us the answer. We measure the material’s resistance to indentation, which tells us a lot about its strength and wear resistance. This is especially critical for parts that face a lot of stress, as it confirms that they have been properly heat-treated and will hold up under tough conditions.

Your Takeaway: Do not overlook these specialized tests, especially for high-stress or critical applications. Ask our team how these additional services can provide the extra layer of assurance you need to maintain safety and compliance.

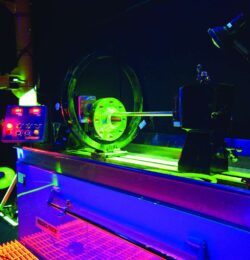

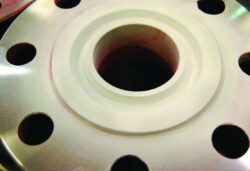

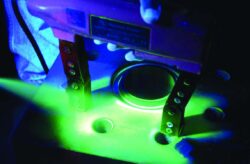

NDT Photo Gallery

Why Partner with Machine Specialty & Manufacturing?

When you need quality assurance you can trust, you need a partner, not just a service provider. We offer something more than just a list of tests. You benefit directly from our in-house expertise. Having our certified technicians on staff means we control the entire process, from start to finish. We don’t have to wait for a third party, and that saves you time and money. Our integrated approach combines NDT seamlessly with our manufacturing and repair work, which streamlines your project and helps you hit your deadlines. You can trust that your components are safe, reliable, and fully compliant with the toughest industry standards. We don’t just deliver parts; we deliver confidence.

Contact us today to discuss a complete, integrated solution that gives you better quality control and a simpler process. We don’t just deliver parts; we deliver confidence.

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.