Table of Contents

Quick Summary:

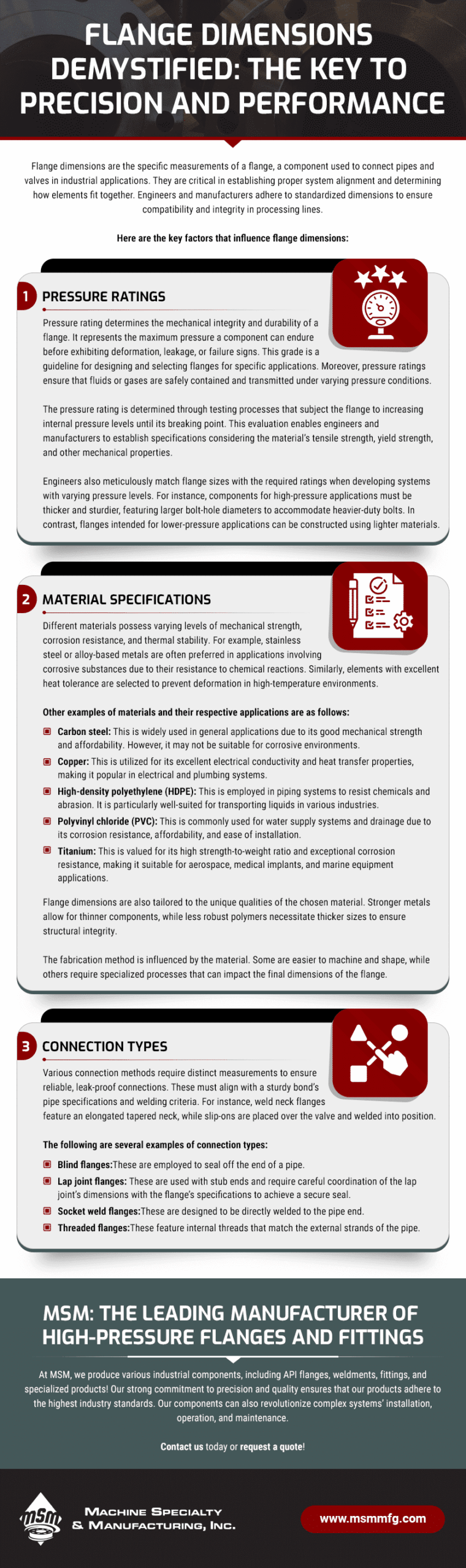

Flange dimensions, essential for connecting pipes and valves, are governed by three primary factors to ensure compatibility and system integrity: Pressure Ratings determine the necessary component thickness and strength for safe operation; Material Specifications (e.g., carbon steel, stainless steel) dictate the flange’s size and design based on mechanical strength and resistance to corrosion or heat; and Connection Types (e.g., weld neck, threaded) require specific measurements for forming a secure, leak-proof bond.

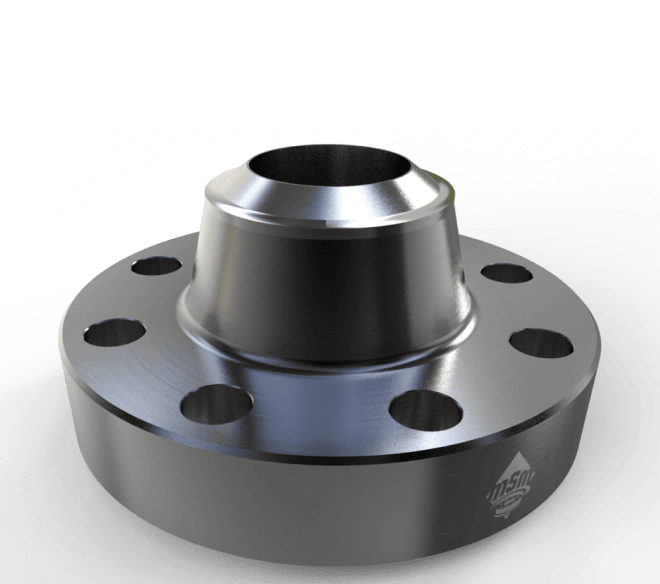

Flange dimensions are the specific measurements of a flange, a component used to connect pipes and valves in industrial applications. They are critical in establishing proper system alignment and determining how elements fit together. Engineers and manufacturers adhere to standardized dimensions to ensure compatibility and integrity in processing lines.

Here are the key factors that influence flange dimensions:

1. Pressure Ratings

Pressure rating determines the mechanical integrity and durability of a flange. It represents the maximum pressure a component can endure before exhibiting deformation, leakage, or failure signs. This grade is a guideline for designing and selecting flanges for specific applications. Moreover, pressure ratings ensure that fluids or gases are safely contained and transmitted under varying pressure conditions.

The pressure rating is determined through testing processes that subject the flange to increasing internal pressure levels until its breaking point. This evaluation enables engineers and manufacturers to establish specifications considering the material’s tensile strength, yield strength, and other mechanical properties.

Engineers also meticulously match flange sizes with the required ratings when developing systems with varying pressure levels. For instance, components for high-pressure applications must be thicker and sturdier, featuring larger bolt-hole diameters to accommodate heavier-duty bolts. In contrast, flanges intended for lower-pressure applications can be constructed using lighter materials.

2. Material Specifications

Different materials possess varying levels of mechanical strength, corrosion resistance, and thermal stability. For example, stainless steel or alloy-based metals are often preferred in applications involving corrosive substances due to their resistance to chemical reactions. Similarly, elements with excellent heat tolerance are selected to prevent deformation in high-temperature environments.

Other examples of materials and their respective applications are as follows:

- Carbon steel: This is widely used in general applications due to its good mechanical strength and affordability. However, it may not be suitable for corrosive environments.

- Copper: This is utilized for its excellent electrical conductivity and heat transfer properties, making it popular in electrical and plumbing systems.

- High-density polyethylene (HDPE): This is employed in piping systems to resist chemicals and abrasion. It is particularly well-suited for transporting liquids in various industries.

- Polyvinyl chloride (PVC): This is commonly used for water supply systems and drainage due to its corrosion resistance, affordability, and ease of installation

- Titanium: This is valued for its high strength-to-weight ratio and exceptional corrosion resistance, making it suitable for aerospace, medical implants, and marine equipment applications.

Flange dimensions are also tailored to the unique qualities of the chosen material. Stronger metals allow for thinner components, while less robust polymers necessitate thicker sizes to ensure structural integrity.

The fabrication method is influenced by the material. Some are easier to machine and shape, while others require specialized processes that can impact the final dimensions of the flange.

3. Connection Types

Various connection methods require distinct measurements to ensure reliable, leak-proof connections. These must align with a sturdy bond’s pipe specifications and welding criteria. For instance, weld neck flanges feature an elongated tapered neck, while slip-ons are placed over the valve and welded into position.

The following are several examples of connection types:

- Threaded flanges:These feature internal threads that match the external strands of the pipe.

- Blind flanges:These are employed to seal off the end of a pipe.

- Lap joint flanges: These are used with stub ends and require careful coordination of the lap joint’s dimensions with the flange’s specifications to achieve a secure seal.

- Socket weld flanges:These are designed to be directly welded to the pipe end.

MSM: The Leading Manufacturer of High-Pressure Flanges and Fittings

At MSM, we produce various industrial components, including API flanges, weldments, fittings, and specialized products! Our strong commitment to precision and quality ensures that our products adhere to the highest industry standards. Our components can also revolutionize complex systems’ installation, operation, and maintenance.

Contact us today or request a quote!

Table of Contents

Additional Blogs

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.