Table of Contents

Quick Summary:

Welding is an indispensable form of metalwork that underpins the manufacturing of 70% of all produced goods, from homes to vehicles, necessitating the careful selection of the right technique for specific materials. Key welding methods include Resistance Welding, which uses electricity and pressure for metals like steel and stainless steel; Shielded Metal Arc Welding (SMAW), an affordable fusion process using a flux-coated electrode for steel, stainless steel, and aluminum; Gas Tungsten Arc Welding (GTAW), known for high-quality results on a wide range of materials including aluminum, titanium, and cast iron, using a non-consumable tungsten electrode and external gas; Gas Metal Arc Welding (GMAW), a fusion method utilizing a consumable electrode and shielding gas for steel, stainless steel, and aluminum; and Flux-Cored Arc Welding (FCAW), another fusion technique that employs a flux-packed consumable wire electrode, primarily for steel and stainless steel.

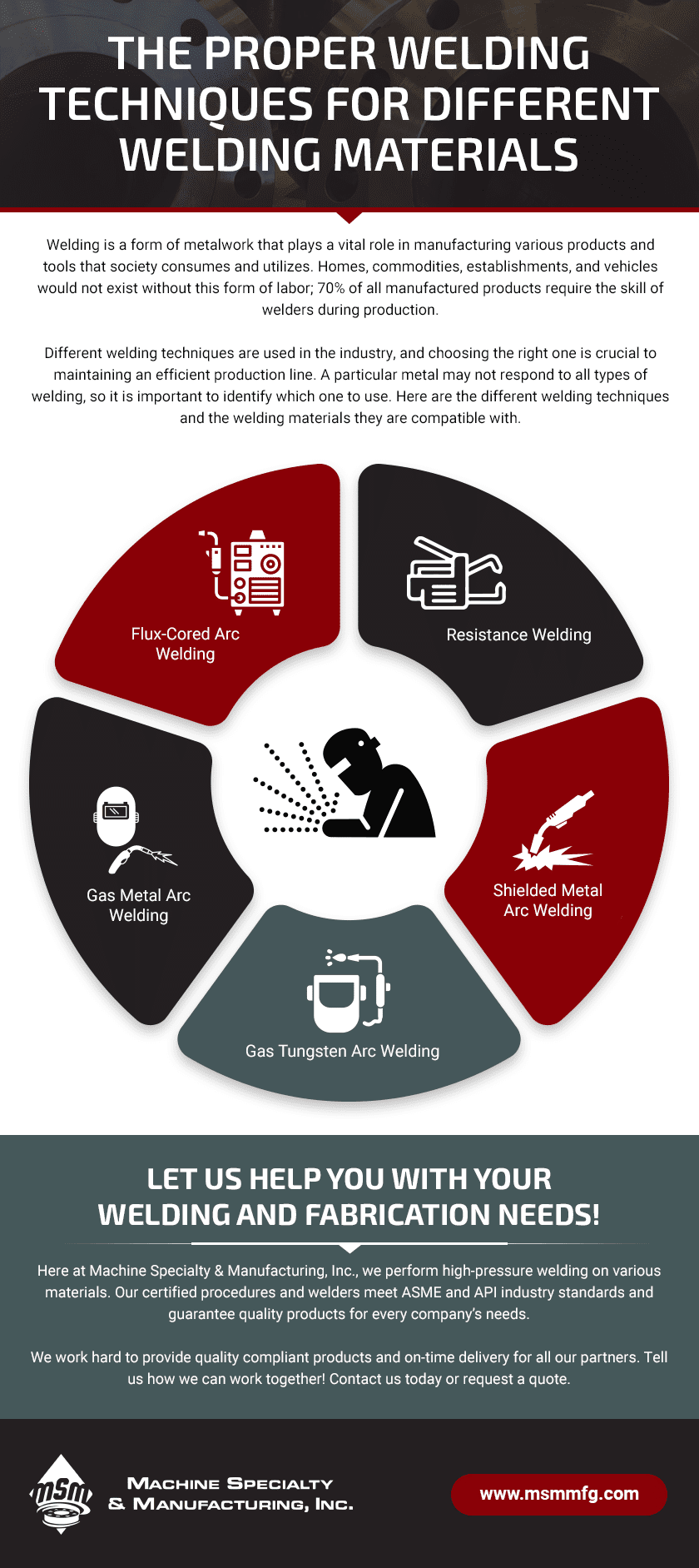

Welding is a form of metalwork that plays a vital role in manufacturing various products and tools that society consumes and utilizes. Homes, commodities, establishments, and vehicles would not exist without this form of labor; 70% of all manufactured products require the skill of welders during production.

Different welding techniques are used in the industry, and choosing the right one is crucial to maintaining an efficient production line. A particular metal may not respond to all types of welding, so it is important to identify which one to use. Here are the different welding techniques and the welding materials they are compatible with.

Resistance Welding

Resistance welding is also called electric resistance welding. This technique joins metal by applying pressure and sending a powerful electric current through the metal to heat up and melt the welding joint and forge them together. Then, the electrode extracts heat from the molten area and forms a weld nugget.

Resistance welding is cost-effective and does not require other materials. It has many types — spot welding, butt welding, and seam welding. In addition, this form is suited for welding materials such as steel or stainless steel.

Shielded Metal Arc Welding

This welding technique is a fusion welding process that uses a consumable and flux-coated electrode. With a shielded metal arc welding technique, the flux on the electrode is melted and surfaces on top of the molten weld pool. This simple and affordable process requires only a constant current power source, an electrode, an electrode holder, and a ground clamp.

The shielded metal arc welding applies materials like steel, stainless steel, and aluminum, which do not require much effort to be welded.

Gas Tungsten Arc Welding

The gas tungsten arc welding technique is widely used for welding similar or dissimilar metals because it yields a sound output with good weld quality. This technique uses an external gas supply and non-consumable tungsten electrodes to form an arc that melts the filler wire to fuse and weld the metal.

The materials gas tungsten arc welding applies to are steel, stainless steel, aluminum titanium, cast iron, and magnesium alloy.

Gas Metal Arc Welding

Gas metal arc welding is also a fusion welding process that uses an electrical arc as the source of energy to cause a metal fusion. For this method, the electrode being is also the filler metal consumable. This method also uses an external shielding gas to protect the molten weld.

Gas metal arc welding applies to steel, stainless steel, and aluminum.

Flux-Cored Arc Welding

The flux-cored arc welding process is also a fusion welding technique. Only this time, the welding process involves using a continuously fed consumable wire electrode packed with flux to create an electrical arc that produces the heat needed to melt the metals.

A flux-cored arc welding technique can be used on welding materials like steel and stainless steel.

Let Us Help You With Your Welding and Fabrication Needs!

Here at Machine Specialty & Manufacturing, Inc., we perform high-pressure welding on various materials. Our certified procedures and welders meet ASME and API industry standards and guarantee quality products for every company’s needs.

We work hard to provide quality compliant products and on-time delivery for all our partners. Tell us how we can work together! Contact us today or request a quote.

Table of Contents

Additional Blogs

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.