Table of Contents

Quick Summary:

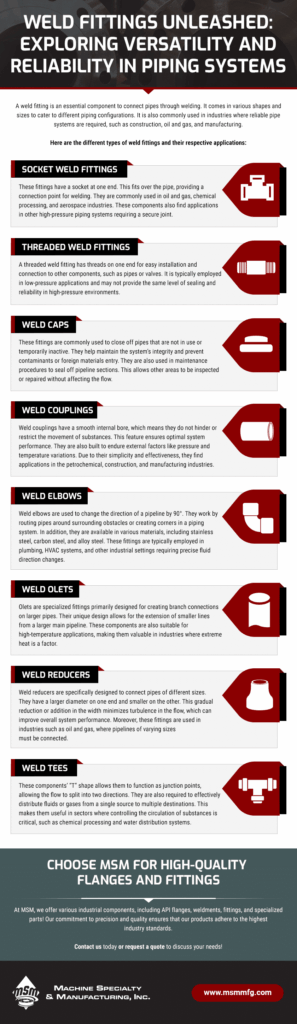

Weld fittings are essential components for joining pipes across industries like oil and gas, utilizing various types for specific purposes: Socket Weld and Threaded Fittings connect pipes, while Weld Caps seal ends. Components like Weld Couplings maintain flow, Weld Elbows change direction, Weld Tees split flow, Weld Reducers connect different pipe sizes, and Weld Olets create branch connections, all contributing to customized and reliable piping systems.

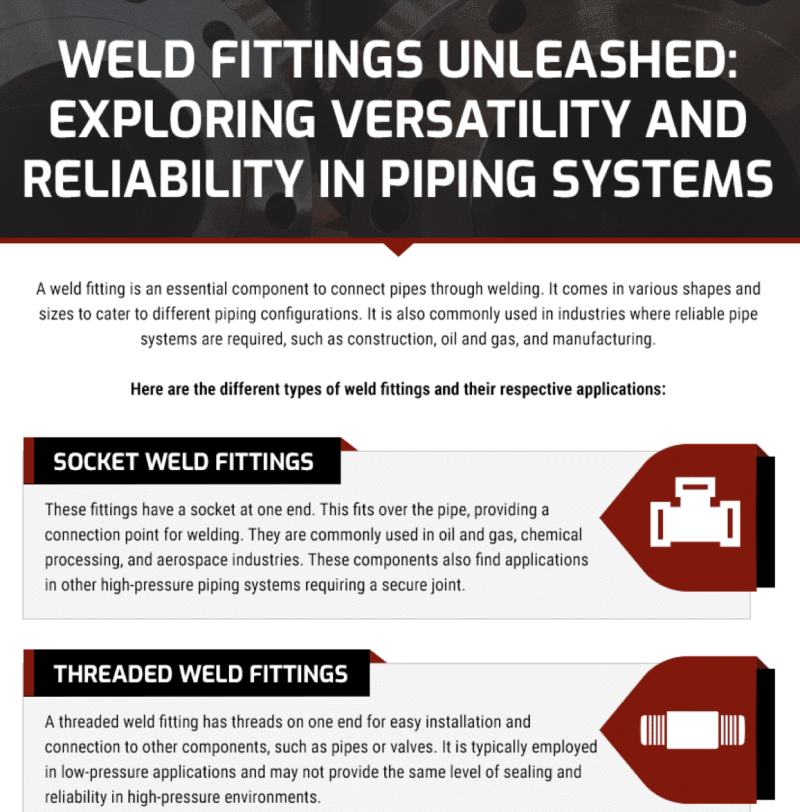

A weld fitting is an essential component to connect pipes through welding. It comes in various shapes and sizes to cater to different piping configurations. It is also commonly used in industries where reliable pipe systems are required, such as construction, oil and gas, and manufacturing.

Here are the different types of weld fittings and their respective applications:

Socket Weld Fittings

These fittings have a socket at one end. This fits over the pipe, providing a connection point for welding. They are commonly used in oil and gas, chemical processing, and aerospace industries. These components also find applications in other high-pressure piping systems requiring a secure joint.

Threaded Weld Fittings

A threaded weld fitting has threads on one end for easy installation and connection to other components, such as pipes or valves. It is typically employed in low-pressure applications and may not provide the same level of sealing and reliability in high-pressure environments.

Weld Caps

These fittings are commonly used to close off pipes that are not in use or temporarily inactive. They help maintain the system’s integrity and prevent contaminants or foreign materials entry. They are also used in maintenance procedures to seal off pipeline sections. This allows other areas to be inspected or repaired without affecting the flow.

Weld Couplings

Weld couplings have a smooth internal bore, which means they do not hinder or restrict the movement of substances. This feature ensures optimal system performance. They are also built to endure external factors like pressure and temperature variations. Due to their simplicity and effectiveness, they find applications in the petrochemical, construction, and manufacturing industries.

Weld Elbows

Weld elbows are used to change the direction of a pipeline by 90°. They work by routing pipes around surrounding obstacles or creating corners in a piping system. In addition, they are available in various materials, including stainless steel, carbon steel, and alloy steel. These fittings are typically employed in plumbing, HVAC systems, and other industrial settings requiring precise fluid direction changes.

Weld Olets

Olets are specialized fittings primarily designed for creating branch connections on larger pipes. Their unique design allows for the extension of smaller lines from a larger main pipeline. These components are also suitable for high-temperature applications, making them valuable in industries where extreme heat is a factor.

Weld Reducers

Weld reducers are specifically designed to connect pipes of different sizes. They have a larger diameter on one end and smaller on the other. This gradual reduction or addition in the width minimizes turbulence in the flow, which can improve overall system performance. Moreover, these fittings are used in industries such as oil and gas, where pipelines of varying sizes must be connected.

Weld Tees

These components’ “T” shape allows them to function as junction points, allowing the flow to split into two directions. They are also required to effectively distribute fluids or gases from a single source to multiple destinations. This makes them useful in sectors where controlling the circulation of substances is critical, such as chemical processing and water distribution systems.

Table of Contents

Additional Blogs

Choose MSM for High-Quality Flanges and Fittings

At MSM, we offer various industrial components, including API flanges, weldments, fittings, and specialized parts! Our commitment to precision and quality ensures that our products adhere to the highest industry standards.