Avoid Costly Pipeline Failures and Project Delays

The Critical Importance of High-Integrity Pipeline Components in Energy Infrastructure Projects

Your pipeline project represents millions of dollars in investment, countless hours of engineering, and most importantly, the safety of communities and workers. When critical energy infrastructure demands the highest level of precision, every component must perform flawlessly under extreme conditions. The stakes are too high for anything less than absolute reliability, and the consequences of failure extend far beyond financial losses to include environmental disasters, regulatory penalties, and irreparable damage to your reputation.

The Challenges You Face

- Sourcing fittings that withstand extreme pressures, high temperatures, and corrosive environments.

- Needing absolute certainty that fittings meet every detail of ASME B16.9 standards for safety and compliance.

- Requiring flawless integration into complex systems, without leaks or premature failures.

The Frustrations You Feel

- The fear of project delays and cost escalations caused by unreliable suppliers or incorrect fittings.

- The immense pressure to prevent leaks and failures, knowing the safety, environmental, and financial consequences.

- The stress of navigating complex compliance standards and avoiding severe penalties for non-conformance.

Your Trusted Partner for Mission-Critical Heavy-Wall & ASME B16.9 Weld Fittings

At MSMMFG, we understand that your success depends on having a reliable partner who shares your commitment to safety, quality, and operational excellence. For over 40 years, we’ve built our reputation by successfully partnering with industry leaders, helping navigate the same complex challenges you face while delivering the high-integrity components that keep critical infrastructure operating safely and efficiently.

|

ISO 9001:2015 Certified Quality Management Systems |

Our comprehensive quality management system ensures every buttwelding fitting meets the highest international standards through rigorous process controls, statistical quality monitoring, and continuous improvement programs. With full material traceability, certified test reports, and comprehensive documentation, you gain the confidence that comes from working with a supplier whose quality systems have been independently verified and continuously audited by third-party certification bodies. |

|

|

Heavy Wall and ASME B16.9 Fitting Specialists |

Our core focus on robust, precisely engineered pipeline solutions means we don’t just supply standard fittings – we deliver engineered confidence through specialized heavy wall capabilities, custom metallurgies, and application-specific designs. Whether you need standard carbon steel fittings, exotic alloy components, or custom-engineered solutions for unique applications, our technical expertise ensures optimal performance in your specific operating environment. |

|

|

Deep Oil & Gas Industry Expertise and Technical Support |

We speak your language and understand the unique challenges of upstream production, midstream transportation, downstream refining, and petrochemical processing applications. Our technical team provides engineering support for material selection, application-specific recommendations, and integration assistance that goes beyond simple product supply to partnership in your project success from initial design through long-term operation. |

|

Comprehensive Range of Factory-Made Buttwelding Fittings Engineered for Superior Performance

We provide an extensive inventory of factory-made wrought buttwelding fittings, fully compliant with ASME B16.9 standards, along with specialized heavy wall solutions engineered for superior performance in the most demanding applications. Our product range includes elbows, tees, reducers, caps, and stub ends in sizes from 1/2″ to 60″ and wall thicknesses up to Schedule XXS, manufactured from carbon steel, stainless steel, alloy steel, and exotic materials including Inconel, Hastelloy, and duplex stainless steels.

|

Carbon & Low Alloy Steel |

4130, 4140, A234 WPB/C, Y42, Y52, Y60, WPL-6 |

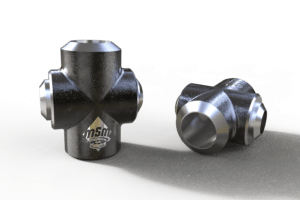

Weld Tee |

|

Carbon Steel |

A234 WPB/C, Y42, Y52, Y60, WPL-6 |

Eccentric Reducer |

|

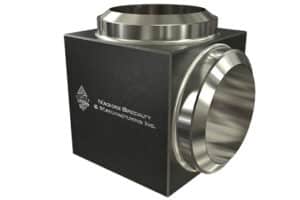

4130 75K Block Style |

For High Pressure Applications |

Butt Weld Block Style Cross |

Your Streamlined Path to Reliable, Mission-Critical Pipeline Components

Making it easy for you to get the mission-critical components you need while ensuring technical accuracy, delivery reliability, and long-term performance is our highest priority. Our proven process eliminates the uncertainties and delays that can derail project schedules while providing the technical support and documentation required for successful project execution.

- Get Your Fittings: Experience our commitment to on-time delivery, ensuring your project stays on track and performs as designed.

- Discuss Your Needs: Schedule a no-obligation consultation. We’ll listen to your requirements, specifications, and timelines.

- Receive a Proposal: We’ll provide a comprehensive, transparent proposal with drawings, material specs, and pricing.

Don’t Wait for a Failure to Happen

Machine Specialty & Manufacturing (MSM) has been delivering high-integrity weld fittings for over 40 years. Proudly Made in the USA.

Secure the integrity of your pipeline with fittings you can trust. Let’s discuss your project today.

Large stocking inventory of sizes and materials.

Quick deliveries on custom/unique builds or items not in stock.

Ready to get started?

Our team is ready to deliver a custom quote that meets your project’s specifications.