Table of Contents

Quick Summary:

Welding cladding is a crucial industrial process that enhances the longevity and durability of components by welding a protective layer of metal onto a base material’s surface. This deposited layer, often ranging from 2 to 20 mm in thickness and applied using techniques like Gas Tungsten Arc Welding or Submerged Arc Welding, is necessary when properties like corrosion or wear resistance cannot be achieved otherwise. Common cladding materials include copper-based weld overlays for seawater protection and Ni Alloy 625 weld overlays for brackish water environments. While it excels at protecting surfaces from wear, corrosion, high temperatures, and impact stress, welding cladding is not intended to strengthen the base part or increase its load capacity. Its applications are vital across various sectors, including power plants, marine equipment, mining machines, and construction.

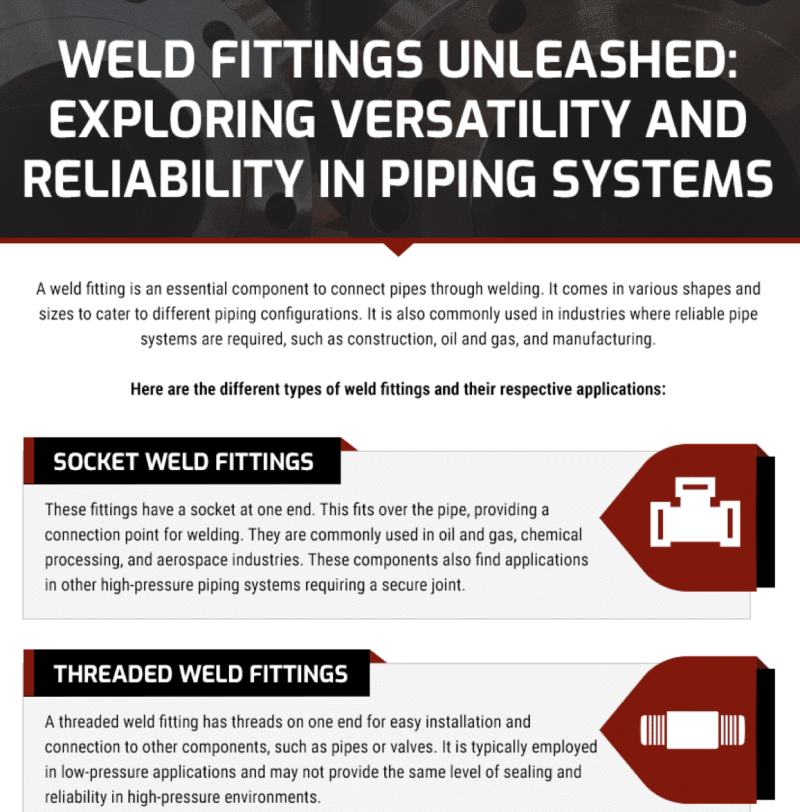

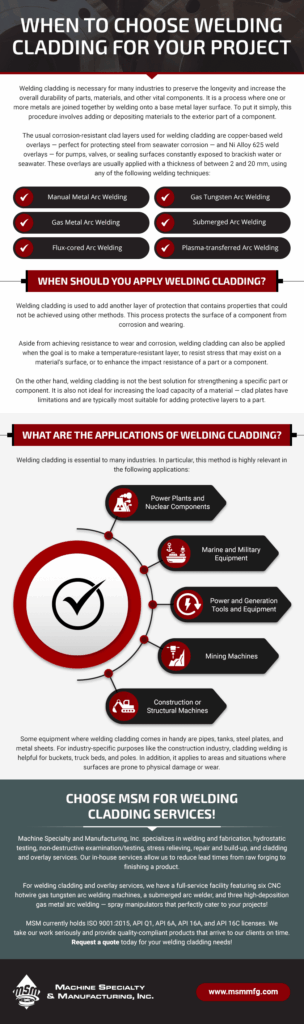

Welding cladding is necessary for many industries to preserve the longevity and increase the overall durability of parts, materials, and other vital components. It is a process where one or more metals are joined together by welding onto a base metal layer surface. To put it simply, this procedure involves adding or depositing materials to the exterior part of a component.

The usual corrosion-resistant clad layers used for welding cladding are copper-based weld overlays — perfect for protecting steel from seawater corrosion — and Ni Alloy 625 weld overlays — for pumps, valves, or sealing surfaces constantly exposed to brackish water or seawater. These overlays are usually applied with a thickness of between 2 and 20 mm, using any of the following welding techniques:

- Plasma-transferred arc welding

- Manual metal arc welding

- Gas tungsten arc welding

- Gas metal arc welding

- Submerged arc welding

- Flux-cored arc welding

When Should You Apply Welding Cladding?

Welding cladding is used to add another layer of protection that contains properties that could not be achieved using other methods. This process protects the surface of a component from corrosion and wearing.

Aside from achieving resistance to wear and corrosion, welding cladding can also be applied when the goal is to make a temperature-resistant layer, to resist stress that may exist on a material’s surface, or to enhance the impact resistance of a part or a component.

On the other hand, welding cladding is not the best solution for strengthening a specific part or component. It is also not ideal for increasing the load capacity of a material — clad plates have limitations and are typically most suitable for adding protective layers to a part.

What Are the Applications of Welding Cladding?

Welding cladding is essential to many industries. In particular, this method is highly relevant in the following applications:

- Power plants and nuclear components

- Marine and military equipment

- Power and generation tools and equipment

- Mining machines

- Construction or structural machines

Some equipment where welding cladding comes in handy are pipes, tanks, steel plates, and metal sheets. For industry-specific purposes like the construction industry, cladding welding is helpful for buckets, truck beds, and poles. In addition, it applies to areas and situations where surfaces are prone to physical damage or wear.

Choose MSM for Welding Cladding Services

Machine Specialty and Manufacturing, Inc. specializes in welding and fabrication, hydrostatic testing, non-destructive examination/testing, stress relieving, repair and build-up, and cladding and overlay services. Our in-house services allow us to reduce lead times from raw forging to finishing a product.

For welding cladding and overlay services, we have a full-service facility featuring six CNC hotwire gas tungsten arc welding machines, a submerged arc welder, and three high-deposition gas metal arc welding — spray manipulators that perfectly cater to your projects!

MSM currently holds ISO 9001:2015, API Q1, API 6A, API 16A, and API 16C licenses. We take our work seriously and provide quality-compliant products that arrive to our clients on time. Request a quote today for your welding cladding needs!

Table of Contents

Additional Blogs

Ready to Get Started?

Our team is ready to deliver a custom quote that meets your project’s specifications.